Production techniques and applications of non-edible GABA

Two production techniques of non-edible GABA are chemical synthesis and bio-transformation by Escherichia coli.

(1)GABA chemical synthesis technique

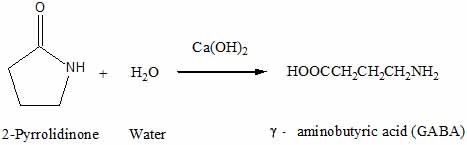

Chemical synthesized GABA is produced from the poisonous 2-pyrrolidinone as raw material. So far, there are more than 20 of domestic manufacturers in China. The concrete procedure is as following. Firstly, 2-pyrrolidinone, calcium hydroxide and water with the certain proportion are put into a reactor. Then it is heated to 120~140°C to keep reaction for 5~10 h. After that, and the solution in the reactor is cooled to 50°C. Next, the supernatant containing GABA is obtained by vacuum filtration or by centrifugation. The following step is that ammonium bicarbonate is added into the supernatant to neutralize calcium ion. Calcium carbonate precipitates, and then is removed by vacuum filtration or by centrifugation. The GABA solution is concentrated by vacuumed processing. Finally, ethanol is fed for GABA crystallization under frozen condition. Reaction principle of GABA synthesis is to open the loop of pyrrolidone, and to add a molecular of water. The production process of GABA is relatively simple. Its cost is very low, the recovery rate of GABA is relatively high, and GABA purity is extremely high, with more than 99.5%. At present, the market price of raw material 2-pyrrolidinone is 25~45 YMB Yuan per kilogram. So the price of chemically synthesized GABA is extremely low, whose market price is 80~100 YMB Yuan per kilogram. It must be mentioned that raw material 2-pyrrolidinone is highly toxic (should be registered in Public Security Bureau if purchased and used). Whatever the production processes of isolation and purification are used to prepare GABA, it is inevitable that the raw material 2-pyrrolidinone remains in product GABA. 2-pyrrolidinone belongs to nerve toxic poison. It mainly causes dysfunction of the central nervous system and diseases of respiratory organs, kidneys and vascular system. The chemically synthesized GABA has typically two applications. The first one is to produce medicine GABA. The second is used as pharmaceutical intermediate, which is the raw material for synthesis of new chemical products, such as 2-hydroxy-4-aminobutyric acid, alendronate, aniracetam, 4-maleic imide butyric acid, 4-dimethyl amino butyric acid hydrochloride, 4-aminobutyric acid methyl ester hydrochloride, and other chemical products. At present, the chemical synthesized GABA is used in feed of poultry and pig. GABA can reduce the animal unconscious movement, decrease energy consumption, so as to achieve the purpose of growth. GABA also promotes animal growth hormone secretion, increase feed intake, and improve the growth rate. Anyway, it is illegal that the chemically synthesized GABA is used as food.

(2) GABA biotransformation by Escherichia coli

Activity of glutamic acid decarboxylase in Escherichia coli is relatively high. It can directly remove a carboxyl group from L-glutamic acid specifically to produce GABA. L-sodium glutamate as raw material can be bio-transformed by Escherichia coli to produce GABA. It also belongs to bio-synthesis method. However, it is known that Escherichia coli are human and animal intestinal bacterium, which primarily exists in human and animal excreta. This kind of bacterium probably remains in product GABA made by the biotransformation method. Eating excessive Escherichia coli can cause people stomach diarrhea, fever, or more serious diseases. GABA by Escherichia coli production cannot be accepted as food, and it does not comply with food laws.